Butt weld Reducing Tee / Unequal Tee

Carbon Steel, Alloy Steel ASME B16.25, ANSI B19.28, MSS-SP-43 Pipe Unequal Tee, Reducing Tee Manufacturer & Supplier in india.

UNEQUAL TEE SPECIFICATION :

Standard - ANSI/ASME :ASTM A403 / ASME SA403, ANSI B16.9, ASME B16.25, ASME B16.28, MSS SP-43.

DIN : DIN2605, DIN2615, DIN2616, DIN2617, DIN28011

EN : EN10253-1, EN10253-2

Schedule : SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS

Type : Seamless / ERW / Welded / Fabricated

Seamless Reducing Tee Size: 1/2"~24"

ERW / Welded / Fabricated Reducing Tee Size: 1/2" (15 NB) to 48" (1200NB)

Form: Unqual Tee, Reducing Tee

EQUAL TEE MATERIAL & GRADES :

Stainless Steel Equal Tee : ASTM A403 WP316/316L, ASTM A403 WP304/304L, ASTM A182 F316L, 304L, DIN 1.4301, DIN1.4306, DIN 1.4401, DIN 1.4404, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L

Carbon Steel Reducing Tee : ASTM A234, ASME SA234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

Alloy Steel Reducing Tee : ASTM A234, ASME SA234 WP1 / WP5 / WP9 / WP11 / WP22 / WP91

Duplex Steel Reducing Tee : ASTM A815, ASME SA815 UNS No S31803, S32205

Super Duplex Reducing Tee : ASTM A815, ASME SA815 UNS No S32750, S32950

Nickel Alloy Reducing Tee : ASTM B336, ASME SB336, Nickel 200 (UNS No. No2200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020), Titanium (Grade I & II)

Low Temperature Carbon Steel Reducing Tee : ASTM A420 WPL3, A420 WPL6

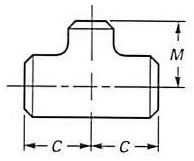

UNEQUAL TEE / REDUCING TEE DIMENSIONS :

| Nominal Pipe Size | Outside diameter at bevel |

Center-to-End | |||

|---|---|---|---|---|---|

| Run | Outlet | Run | Outlet | Run (C) | Outlet (M) |

1/2" |

1/4" 3/8" |

21.3 |

13.7 17.3 |

25 |

25 |

3/4" |

3/8" 1/2" |

26.7 |

17.3 21.3 |

29 |

29 |

1" |

1/2" 3/4" |

33.4 |

21.3 26.7 |

38 |

38 |

1 1/4" |

1/2" 3/4" 1" |

42.2 |

21.3 26.7 33.4 |

48 |

48 |

1 1/2" |

1/2" 3/4" 1" 1 1/4" |

48.3 |

21.3 26.7 33.4 42.2 |

57 |

57 |

2" |

3/4" 1" 1 1/4" 1 1/2" |

60.3 |

26.7 33.4 42.2 48.3 |

64 |

44 51 57 60 |

2 1/2" |

1" 1 1/4" 1 1/2" 2" |

73.0 |

33.4 42.2 48.3 60.3 |

76 |

57 64 67 70 |

3" |

1 1/4" 1 1/2" 2" 2 1/2" |

88.9 |

42.2 48.3 60.3 73.0 |

86 |

70 73 76 83 |

3 1/2" |

1 1/2" 2" 2 1/2" 3" |

101.6 |

48.3 60.3 73.0 88.9 |

95 |

79 83 89 92 |

4" |

1 1/2" 2" 2 1/2" 3" 3 1/2" |

114.3 |

48.3 60.3 73.0 88.9 101.6 |

105 |

86 89 95 98 102 |

5" |

2" 2 1/2" 3" 3 1/2" 4" |

141.3 |

60.3 73.0 88.9 101.6 114.3 |

124 |

105 108 111 114 117 |

6" |

2 1/2" 3" 3 1/2" 4" 5 |

168.3 |

73.0 88.9 101.6 114.3 141.3 |

143 |

121 124 127 130 137 |

8" |

3 1/2" 4" 5" 6" |

219.1 |

101.6 114.3 141.3 168.3 |

178 |

152 156 162 168 |

10" |

4" 5" 6" 8" |

273.0 |

114.3 141.3 168.3 219.1 |

216 |

184 191 194 203 |

12" |

5" 6" 8" 10" |

323.8 |

141.3 168.3 219.1 273.0 |

254 |

216 219 229 241 |

14" |

6" 8" 10" 12" |

355.6 |

168.3 219.1 273.0 323.8 |

279 |

238 248 257 270 |

16" |

6" 8" 10" 12" 14" |

406.4 |

168.3 219.1 273.0 323.8 355.6 |

305 |

264 273 283 295 305 |

18" |

8" 10" 12" 14" 16" |

457.0 |

219.1 273.0 323.8 355.6 406.4 |

343 |

298 308 321 330 330 |

20" |

8" 10" 12" 14" 16" 18" |

508.0 |

219.1 273.0 323.8 355.6 406.4 457.0 |

381 |

324 333 346 356 356 368 |

22" |

10" 12" 14" 16" 18" 20" |

559.0 |

273.0 323.8 355.6 406.4 457.0 508.0 |

419 |

359 371 381 381 394 406 |

24" |

10" 12" 14" 16" 18" 20" 22" |

610.0 |

273.0 323.8 355.6 406.4 457.0 508.0 559.0 |

432 |

384 397 406 406 419 432 432 |

Source : ASME B16.9 - 2007

Marking & Packing

Our products like flanges are packaged to make sure that there’s no damage throughout transit. Just in case of exports, customary export packaging is completed in wooden boxes or cases. All flanges are marked with Trademark (Company’s LOGO), Grade, Size and Lot No. On requests we can do custom marking on our products.Test Certificates

Manufacturer Test Certificate as per EN 10204-3.1, EN 10204-3.2, Raw Materials Certificate, NABL approved Lab Test Report, 100% Radiography Test Report, Third Party Inspection Report etc.Manufacturing Products

- Equal Tee

- Reducing Tee

- Split Tees

- Equal Cross

- Reducing Cross

- Reducers

- Concentric Reducer

- Eccentric Reducer

- Stub End

- Lap Joint Stub Ends

- Long Stubend

- Short Stubend

- Pipe Cap

- End Cap

- Collar

- Swedge Nipple

- Pipe Nipples

- Barrel Nipple

- Reducing Nipple

- Bend

- Long Radius Bend

- Piggable Bend

- Lateral Tee

- 90° Long Radius Elbow

- 90° Short Radius Elbow

- 45° Long Radius Elbow

- 45° Short Radius Elbow

- 180° Long Radius Elbow

- 180° Short Radius Elbow

- 1D Elbow

- 1.5D Elbow

- 3D Elbow

- 5D Elbow

- Reducing Elbow

- Seamless Buttwelding 45° & 90° Elbows

- Welded Elbows

- Seamless Buttwelding 180° Returns

- Straight Tees and Crosses

- Reducing Outlet Tees & Reducing Outlet Crosses

- Cushion Tee